Cleaner Brick Manufacturing in Bangladesh

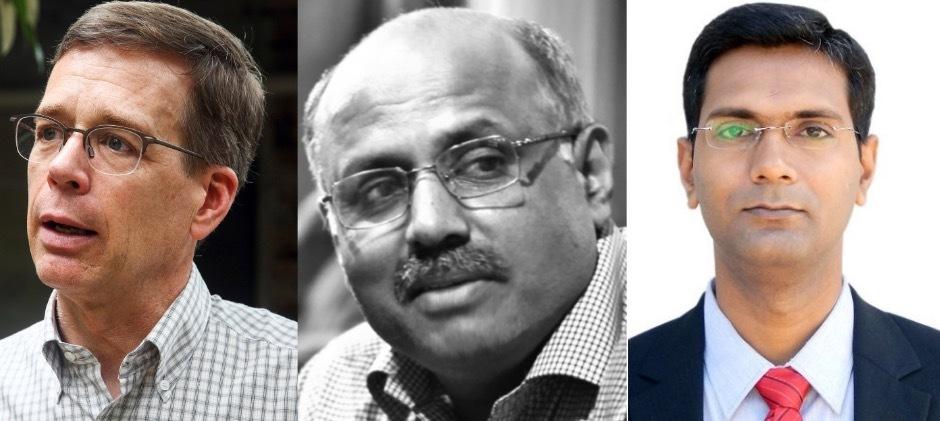

Brick manufacturing creates a substantial number of jobs in Bangladesh and is a big part of the economy. The kilns used to make bricks also generate enormous pollution. Stephen Luby, professor of medicine at Stanford University and senior fellow at the Woods Institute of the Environment, Sameer Maithel, director of Greentech Knowledge Solutions in New Delhi, India, and Debashish Biswas, assistant scientist at Bangladesh-based health research institute icddr, b, describe the work their team of scientists, brick manufacturing association members, and clean energy advisors are doing to create cleaner and still profitable brick manufacturing. Their impact lab is one of six to receive start-up funding from Stanford Impact Labs for 2021-2023.

What is the social problem you are working on?

STEPHEN LUBY (Stanford): We are working to reduce air pollution and greenhouse gas emissions generated by brick kilns in Bangladesh. Brick manufacturing is expanding rapidly to provide building materials for the growing country. Dhaka, the capital city in Bangladesh, is already amongst the most polluted cities in the world. This air pollution kills thousands of Dhaka residents each year. The black carbon generated by the brick kilns is also worsening climate change. We plan to work with kiln owners to increase adoption of approaches that will improve combustion efficiency, generate substantially less air pollution, and increase kiln profits.

SAMEER MAITHEL (Greentech Knowledge Solutions): Small enterprises like brick manufacturing enterprises play a critical role in the economies of South Asian countries. They provide employment to millions of workers. However, they are also an important contributor in air pollution and environment degradation. Adoption of appropriate cleaner production technologies and processes is central to the future sustainability of these enterprises. Greentech is working to identify and develop technologies and facilitate faster dissemination among the small enterprises.

DEBASHISH BISWAS (icddr, b): We aim to reduce the amount of small particulate matter pollution in Bangladesh that has detrimental health effects. Among the known sources of air pollution in Dhaka, the brick kiln industry pollutes more black carbon and is responsible for 30-50 percent of particulate matter. However, we can’t stop brick manufacturing because bricks are the main construction materials in Bangladesh and rapid urbanization has increased demand. This is a complex problem that includes engineering problems as well as financial, technical, social, and political problems. Reducing emissions from brick manufacturing by using simple, effective and feasible strategies will improve the respiratory and cardiovascular health of residents in Bangladesh.

What will the start-up lab funding and team approach help you do?

STEPHEN LUBY (Stanford): The start-up lab funding allows us to apply the creativity, rigorous methods and scholarly knowledge that characterizes Stanford University and focus it on a substantive social problem in the world--a problem that has been largely neglected by scholarly inquiry. This is different from typical university research because it prioritizes addressing the social problem in the world.

SAMEER MAITHEL (Greentech Knowledge Solutions): The start-up lab funding and team approach will help us experiment with and measure the effectiveness of different approaches to disseminate knowledge on cleaner production technologies and their adoption among the small enterprises.

DEBASHISH BISWAS (icddr, b): Traditional brick kilns contribute to the heavy burden of air pollution in our country, particularly in Dhaka and its surroundings. At icddr,b, we have been involved in research about brick kilns with Stanford University for a number of years. To reduce particulate matter pollution from brick kilns and improve health, we will need to consider the views of a diverse and broad group of collaborators. This work creates an opportunity for a team approach to solve a complex problem. It means we have the relevant expertise on board from the beginning for project development, planning, testing, and implementation. It also helps us get appropriate technology.

The collaboration has great mutual benefits between north and south collaborators.Stanford University has extensive experience in providing technical assistance. We believe the project will build capacity of local stakeholders to understand and take action to reduce emissions from brick kilns. In turn, our collaboration will strengthen Stanford research with practical understanding of the problem and an opportunity to put research into practice.

What are you most excited about with this work?

STEPHEN LUBY (Stanford): The opportunity to move from defining the problem and imagining potential interventions to implementing and evaluating solutions, while working closely with partners.

SAMEER MAITHEL (Greentech Knowledge Solutions): The most exciting part is getting an opportunity to work with a multi-disciplinary and multi-country team of public health specialists, social scientists, engineers, brick kiln owners and workers.

DEBASHISH BISWAS (icddr, b): This work will build strong links between researchers, implementation partners, academics, regulatory bodies, entrepreneurs, and policymakers working to decrease emissions. If we can reduce emissions with a low cost solution, we can expect bigger changes in brick kiln industries and an opportunity to scale up in south Asia and other places.